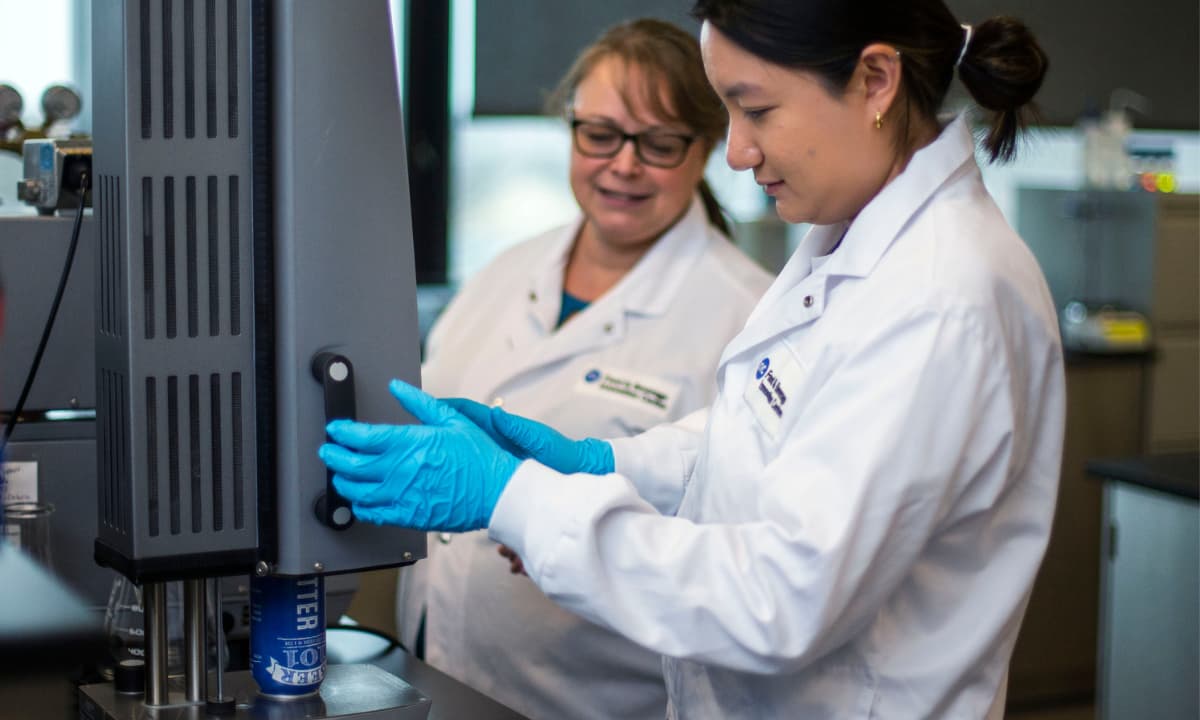

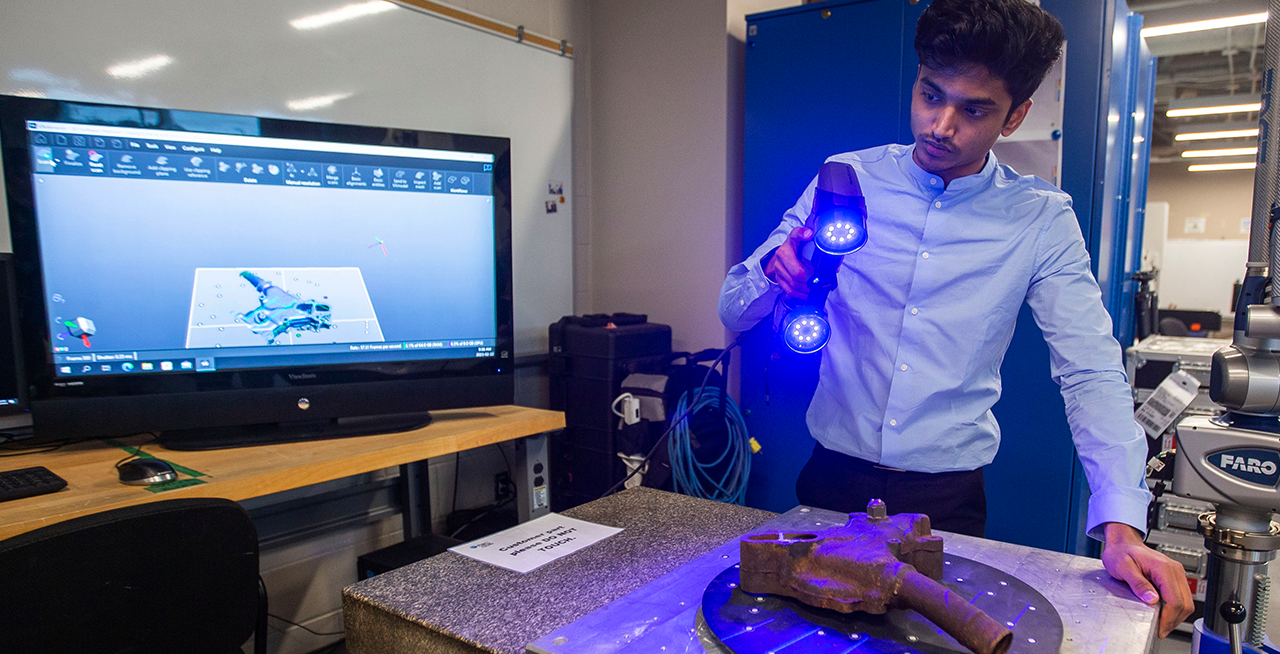

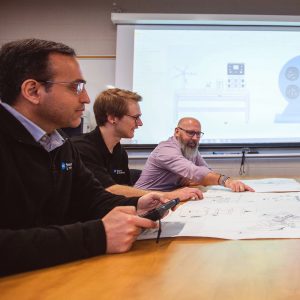

At Niagara College’s Walker Advanced Manufacturing Innovation Centre (WAMIC) you can access leading technologies, equipment and software, as well as expert staff and students to support your innovation goals.

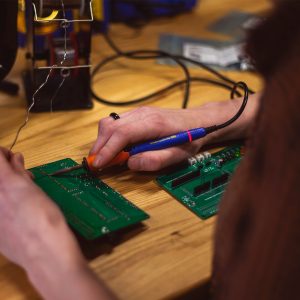

We support manufacturers in automotive, aerospace, agri-food, and machinery manufacturing with a range of metrology services; mechanical, electronic and mechatronic design; and adoption of Industry 4.0 technologies. Read on to learn more and start the conversation.