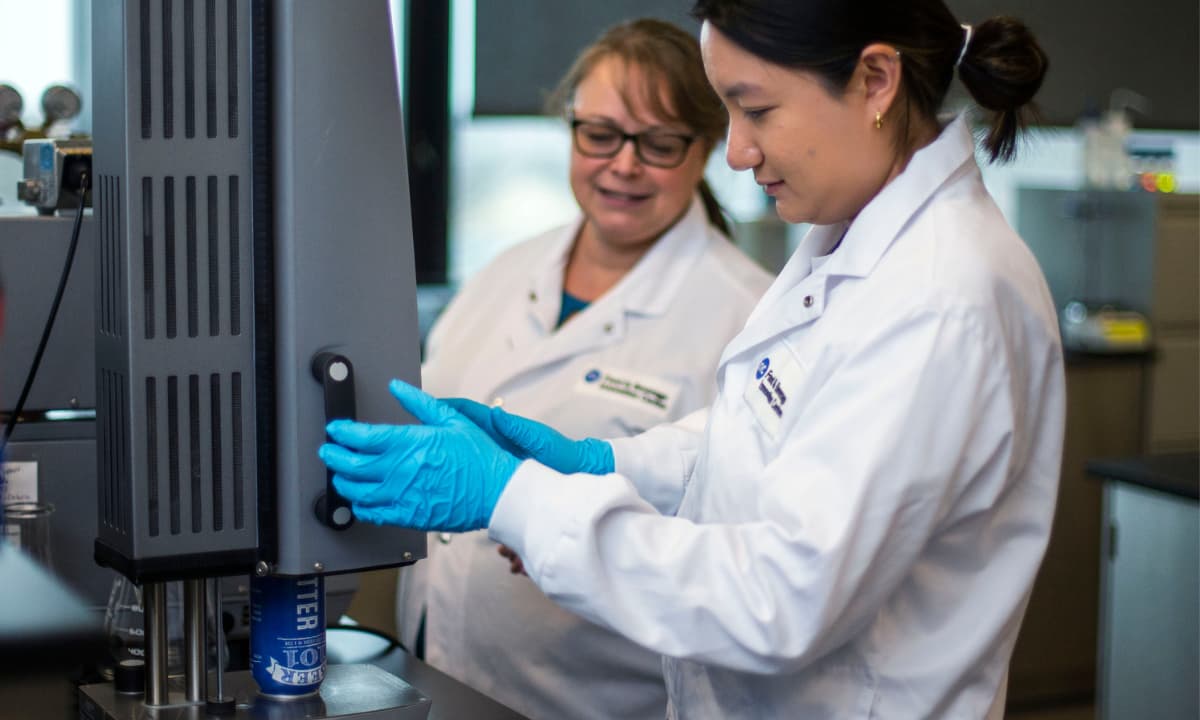

Beverage innovators across Canada will benefit from Niagara College’s newly expanded Pilot Plant, designed to accelerate product development and help businesses bring new beverages to market with greater speed, safety, and confidence.

NC’s Food and Beverage Innovation Centre (FBIC) has unveiled a sweeping renovation of its Beverage Pilot Plant, reinforcing its role as a national leader in applied research and commercialization for Canada’s beverage sector.

The renovation, recently completed at the Daniel J. Patterson Campus in Niagara-on-the-Lake, involved a significant reconfiguration and expansion of existing infrastructure to improve efficiency, increase production capacity, and further support the growing needs of Canadian beverage entrepreneurs.

The upgraded line now features an automated canning system with a rotary infeed, rinse-and-code station, nitrogen-dosed filler/seamer, tunnel pasteurizer, and dryers, plus an additional 350-litre process tank that boosts run sizes from 200 litres to 600 litres (roughly 500-1,600 cans per batch). These assets provide an ideal way for small companies to scale up, since they specifically target the “0-to-100 case” gap many emerging brands face before meeting co-manufacturer minimums.

![http://[Banner]%20Pilot%20Plant%20Production%20Specialist%20Brad%20Barta%20and%20student%20researcher%20Anthony%20Akoh%20in%20the%20Pilot%20Plant%20production%20lab.](https://www.ncinnovation.ca/wp-content/uploads/2025/10/PIlotPlant_AnthonyBrad2024.png)