For more than 50 years, Beamsville, Ont.’s Zwart Systems has been designing and manufacturing custom horticultural technology solutions for the greenhouse industry across North America.

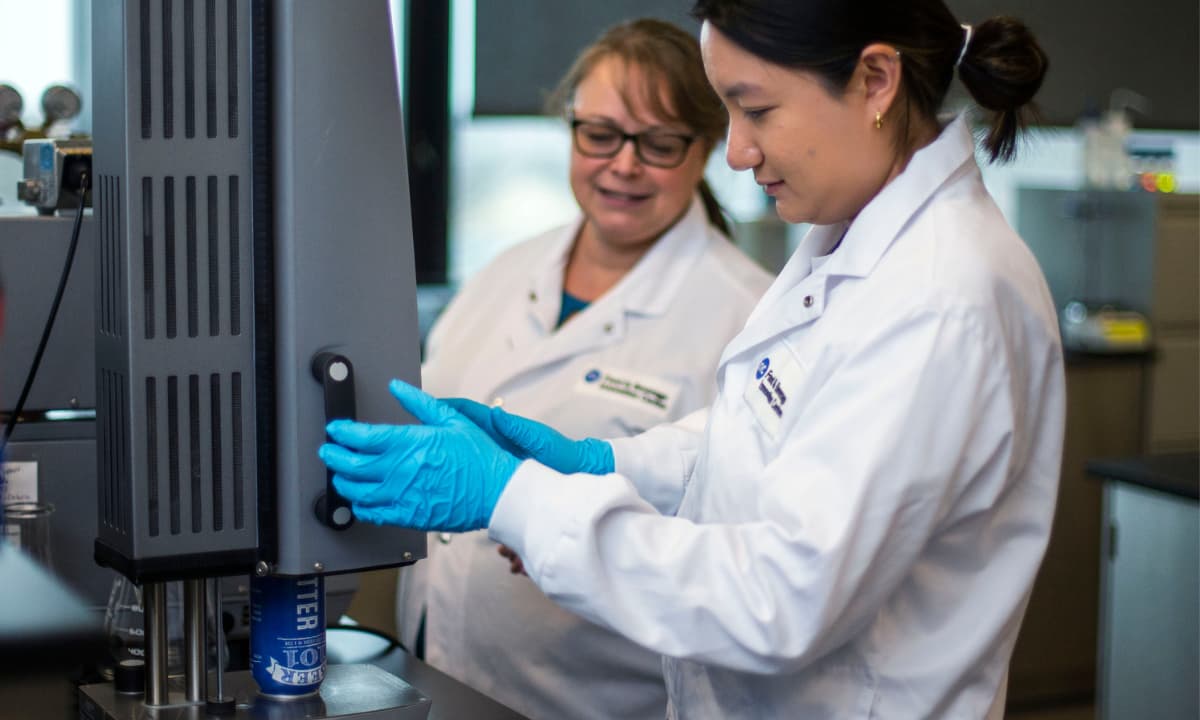

With the aim of expanding its product line to offer a lower-cost growing option for the microgreens, cannabis and vegetable industry, the company designed a vertical growing system and partnered with Research and Innovation’s Agriculture & Environmental Technologies Innovation Centre (AETIC) (now known as the Horticultural and Environmental Sciences Innovation Centre) for research and validation of the system engineering and efficacy.

In an effort to grow more on the same footprint, the role of vertical farming is gaining in popularity. Vertical growing can take many forms, from trellising cucumbers to growing lettuce in PVC pipes, says Felix Pozojevic, a second-year student in NC’s Greenhouse Technician program and a research assistant for this AETIC project.

“Vertical growing allows for farmers to use other mediums for plants to grow in. This can include spun volcanic rock (Rockwool), coconut husks (coir), or even no substrate at all (aeroponics),” explains Pozojevic. “These growing alternatives are reactions to changing environmental conditions, lack of land access, increased food demands, and increased pressure for low food prices.”

Currently, the market believes that to grow floating lettuce requires 6″ to 12″ of continuously moving water. This is at great expense to the grower from a number of standpoints, water usage is chiefly among them. Other factors include the cost of the system infrastructure to achieve this water depth, as well as difficulties managing the wastewater.

Through the applied research project, the goal was to test the multi-tiered growing system for greenhouse application using various crops, in hopes the Zwart Systems growing rack could bring a new option to the market for floating lettuce growth, and other crops in a water depth less than the current market thinking.

Zwart Systems’ product has four levels, utilizing the bottom level for ebb and flood production – a technique to deliver water and nutrients to plants – while the remaining three levels are equipped with misting nozzles, ideal for seed germination or cutting propagation. The goal is to conserve water and space, as prices for both resources continue to soar for greenhouse operators.