News and Publications

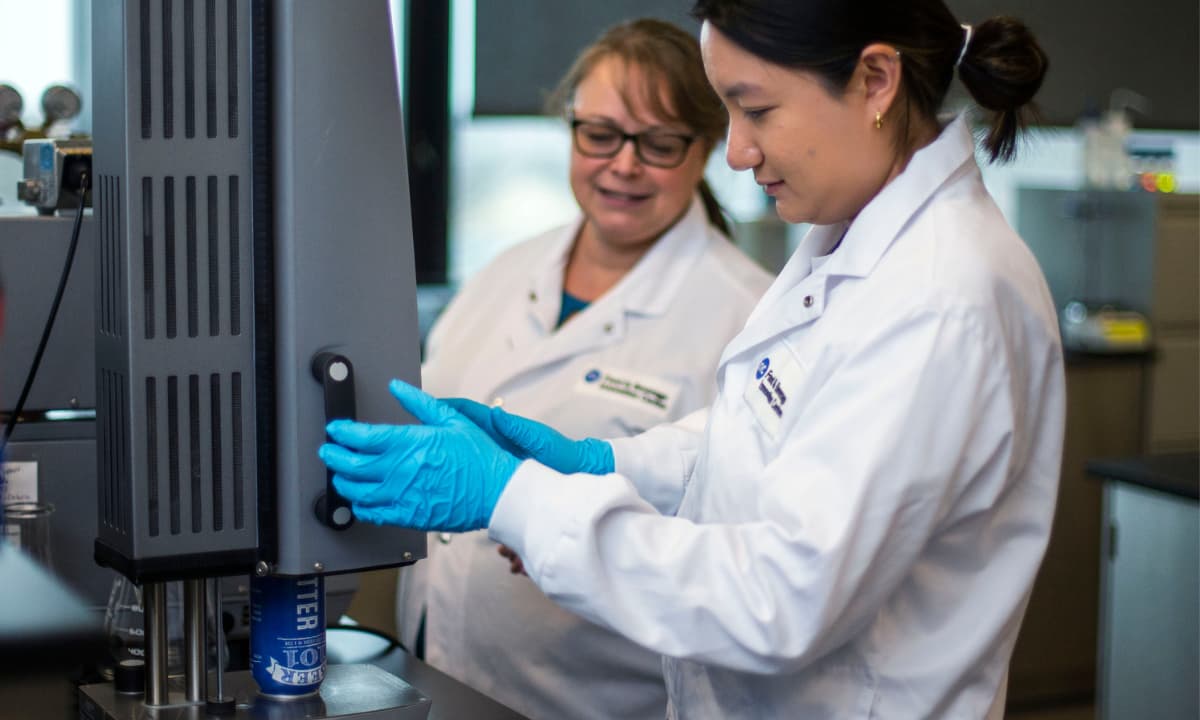

Pepper trial gains unexpected benefits for many in the community

A growth trial to improve product quality has produced the unexpected yield of addressing food insecurity...

Niagara College earns third Technology Access Centre with federal funding investment

R&I been granted its third Technology Access Centre (TAC) for Horticultural and Environmental Sciences (HESIC)