News and Publications

Niagara College earns No. 1 research college in Canada for second year in a row

Niagara College has secured the No. 1 ranking for colleges in Canada for research funding.

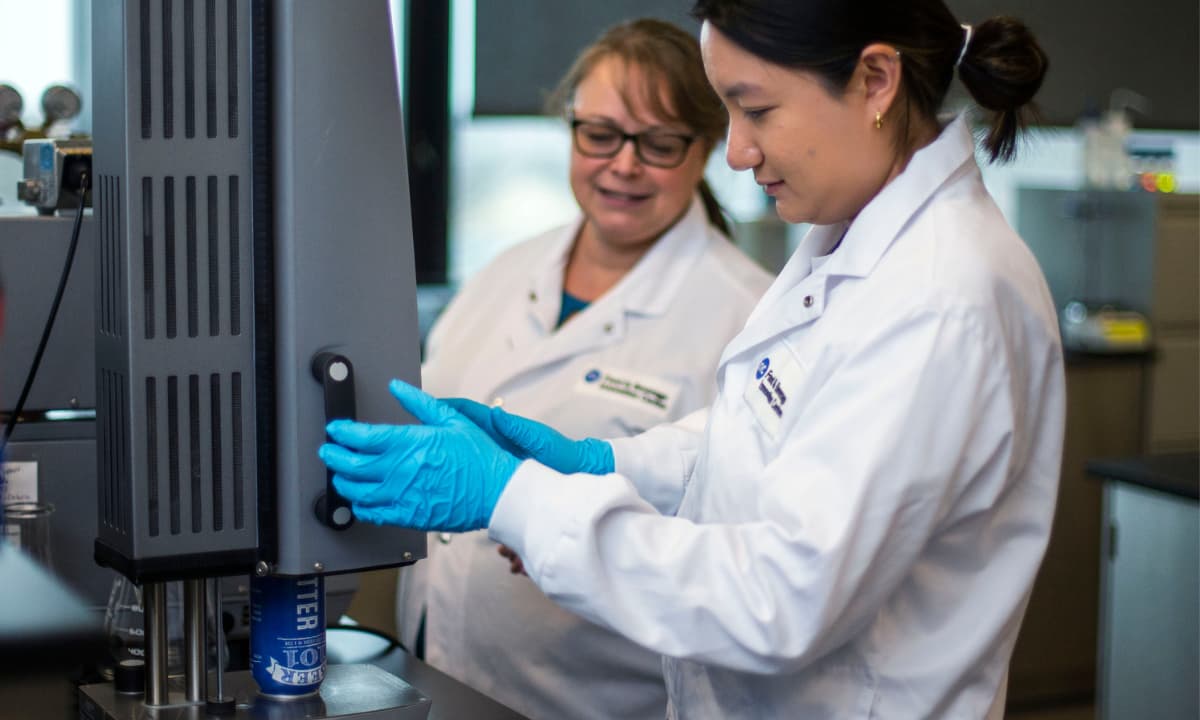

Niagara College earns third Technology Access Centre with federal funding investment

R&I been granted its third Technology Access Centre (TAC) for Horticultural and Environmental Sciences (HESIC)

![[Preview] Pilot Plant Production Specialist Brad Barta and student researcher Anthony Akoh in the Pilot Plant production lab.](https://www.ncinnovation.ca/wp-content/uploads/2025/10/PilotPlant_AnthonyBrad.png)