News and Publications

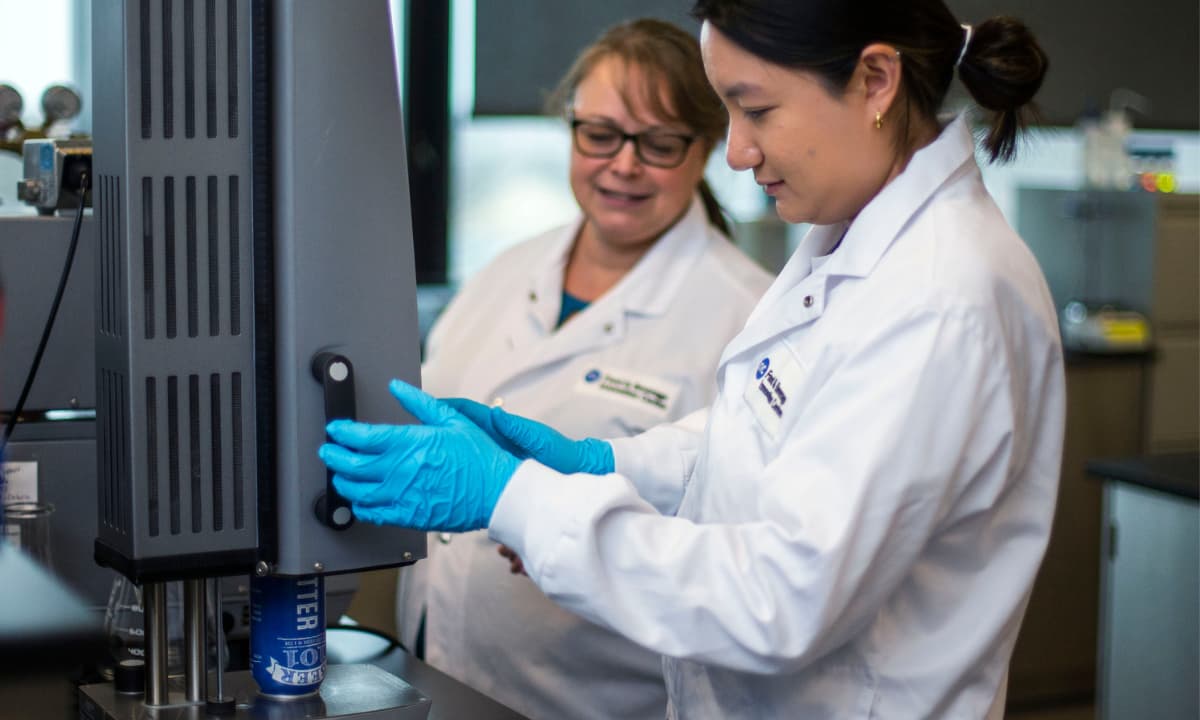

Niagara College earns No. 1 research college in Canada for second year in a row

Niagara College has secured the No. 1 ranking for colleges in Canada for research funding.

In case you missed it: View R&I’s 2023-24 Annual Report

In case you missed it: Research and Innovation's 2023-24 Annual Report is now live. View it here.

R&I By the Numbers: 2023-24

A look at R&I's 24th year of accomplishments as a division of NC and through our innovation centres.