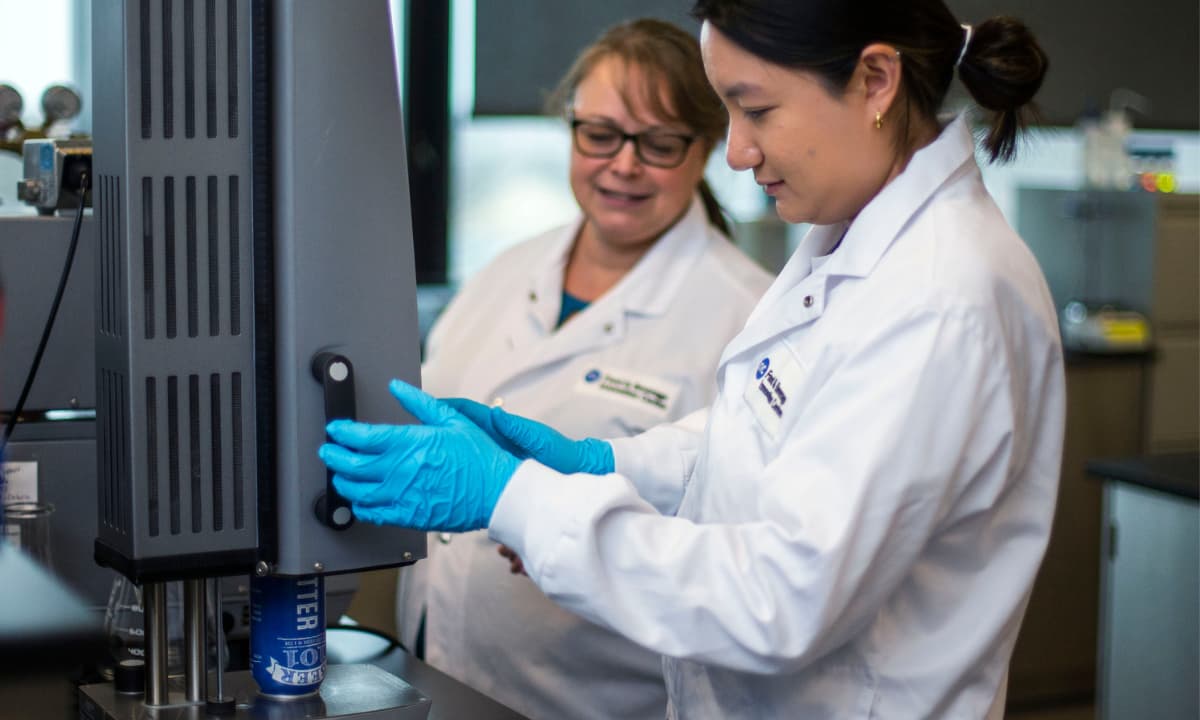

The Food and Beverage Innovation Centre (FBIC) offers a full suite of services to support industry innovation and commercialization of new food and beverage products and processes. We are ready to be your partners in the next great chapter of your company’s evolution.

From new recipe and concept development to shelf-life testing, prototyping, and small batch processing, the FBIC pairs industry partners with our highly qualified staff, faculty, recent graduates and students with the right expertise and equipment to meet their needs. Read on to learn about our specialties, as well as how to connect to start the conversation today.