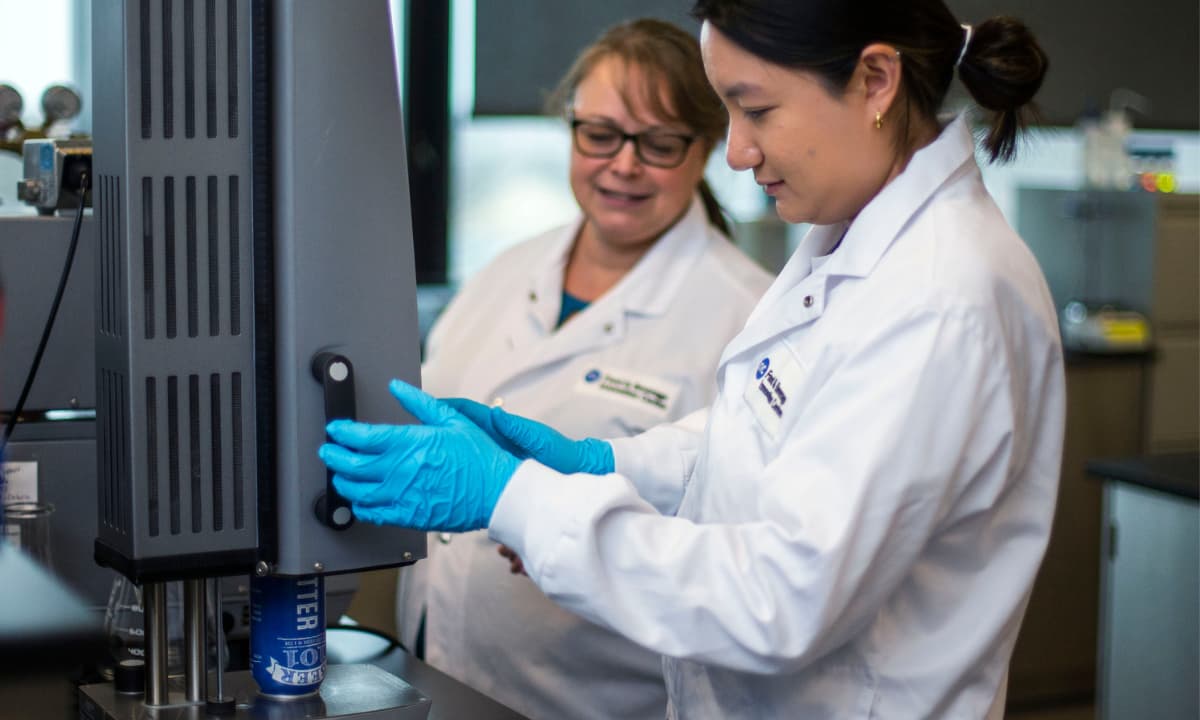

We are the Research and Innovation team – a dynamic group of innovative thinkers dedicated to providing solutions for industry.

Our collective strength lies in our diverse expertise and collaborative spirit, and comprises specialists from various fields, including administration, finance and operations, project management, business development, proposal development, marketing and communications, advanced manufacturing, food and beverage, horticultural and environmental sciences, and commercialization.

Each team member brings a unique perspective and a wealth of experience, allowing us to approach challenges from multiple angles and develop innovative solutions that are both practical and visionary. We are committed to fostering a culture that is welcoming, passionate, trailblazing, and student focused. Together, we strive to make a meaningful impact, delivering solutions that not only address current needs, but also anticipate future challenges and opportunities.

We provide real-world solutions for business, industry, and the community, through applied research and knowledge-transfer activities. Each team pairs industry partners with highly qualified and experienced staff researchers, faculty, recent graduates, and students, with the expertise to meet applied research and innovation needs in many areas.