Project Highlights: Digital landscape meets manufacturing world

MTech Hub, a network created by a Burlington-based software development company Seradex, represents small- and medium-sized manufacturers devoted to exploring and introducing the digital landscape into their businesses. They came to Research & Innovation last May to develop an Internet of Things (IoT) sensor solution that would measure equipment voltage in an attempt to mitigate long-term repair costs and reduce energy consumption.

Seradex is a Burlington-based software development company focused on the development of enterprise resource planning (ERP) software that is geared economically towards SME manufacturers. Commonly, this kind of software is created and costed out for large enterprises. Working against the grain, Seradex has developed a platform that offers the opportunity for the SME manufacturing market to make use of large enterprise ERP tools at a fraction of the cost. To extend this, Seradex created the MTech (Manufacturing Technology) Hub. MTech consists of a network of SME manufacturers that seek to overcome common industry business challenges through the use and adoption of digital technologies. The latest challenge identified was in monitoring manufacturing equipment activity in an attempt to mitigate repair costs and high energy consumption.

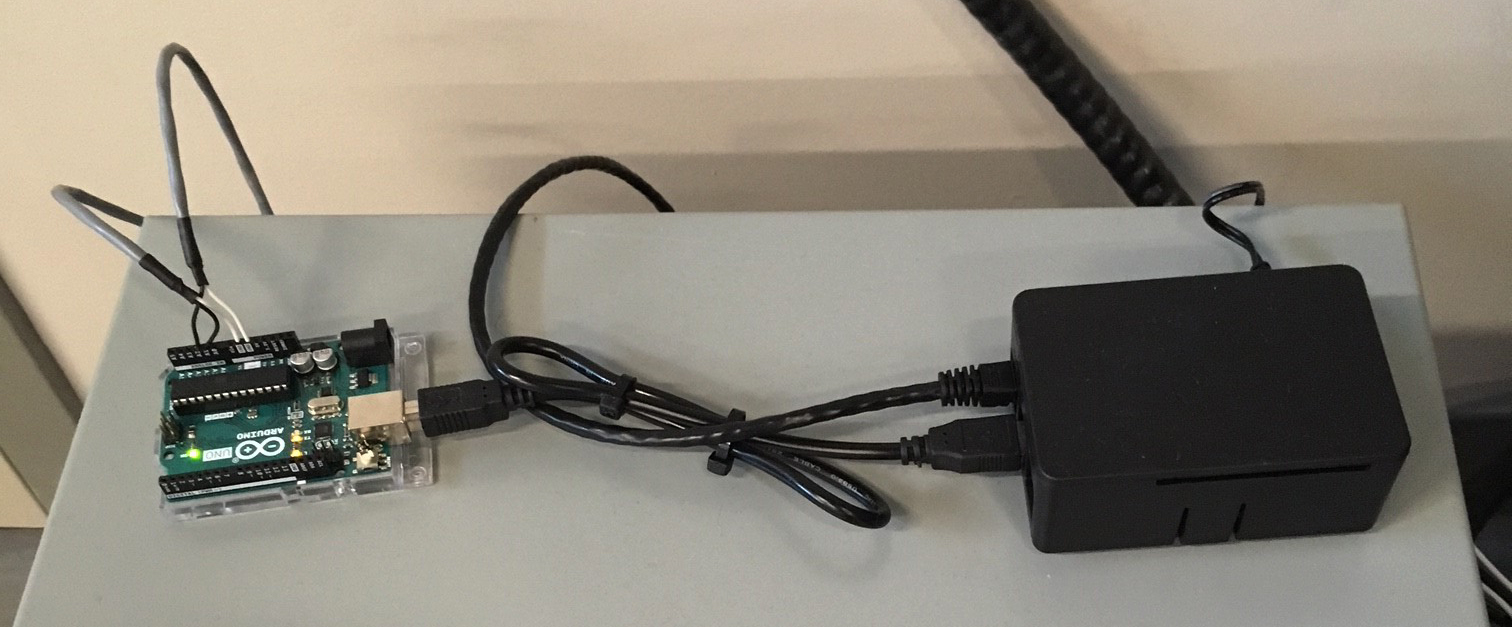

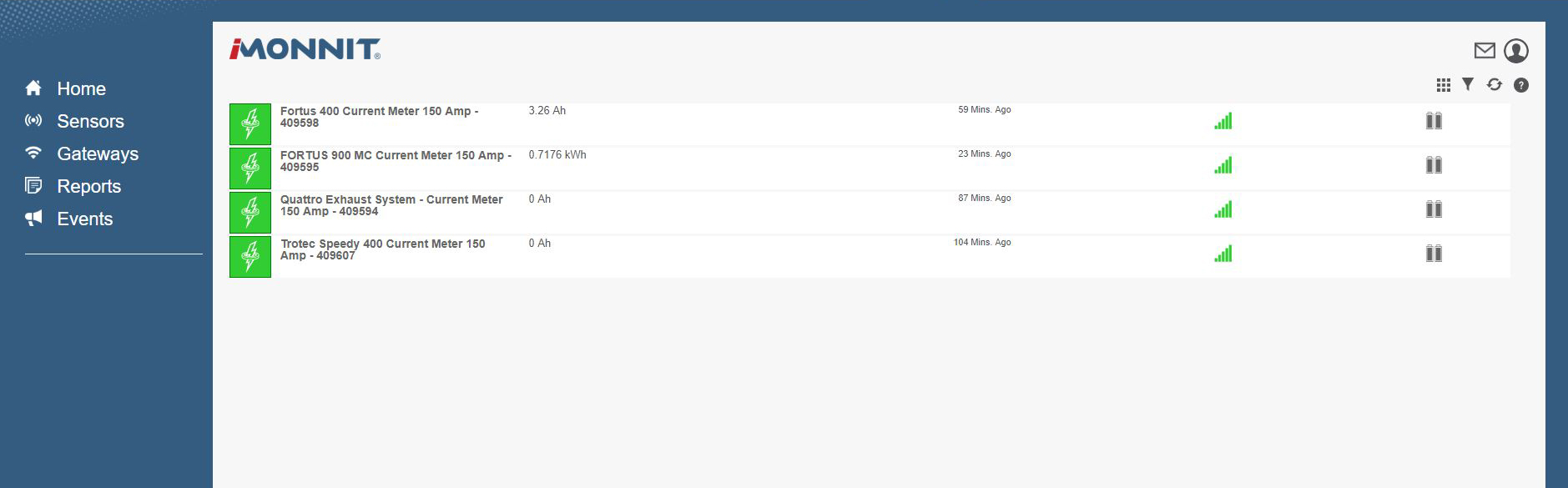

For this project, Walker Advanced Manufacturing Innovation Centre (WAMIC) and the Digital Media & Web Solutions teams were able to identify wireless voltage sensors already in the market that could be retrofitted to existing equipment. For testing purposes, WAMIC’s 3D printers were outfitted with numerous sensors to get an idea of what voltage levels would look like. A comparison was also conducted to determine the accuracy and setup ease for different brands of sensors.

Ksenia Daich, a co-op student from the college’s Computer Programmer Analyst program and member of the Digital Media and Web Solutions team, developed a database for storing sensor readings, along with an internal real-time dashboard for the WAMIC team to use as a monitoring tool. As a result, the team was given an immensely valuable overview of the equipment’s daily activity.

With the results in hand, Seradex and Research & Innovation were both able to better understand how IoT sensors could mitigate high-energy consumption and equipment repair costs. Furthermore, this was a stepping stone in understanding how sensors can improve everyday processes without spending a lot of money, because each sensor that was found could be retrofitted to existing machinery with ease. Based on the research team’s sensor recommendations, the next step for Seradex is to build out monitoring software that can then be commercially distributed through the MTech Hub network of SME manufacturers.